Facilities at Nano System Solutions

The facilities at Nano System Solutions’ headquarters in Okinawa and the environment are carefully though out to provide world class, cutting-edge technology.

First cleanroom in Okinawa

What is a cleanroom?

A cleanroom is an enclosed facility that shuts out the outer air, and the purity of the air inside is secured. Also, the ingredients, the equipment, and the people coming in are under strict supervision so they do not bring dust (waste and impurities) into the room.

Cleanrooms are necessary for semiconductor manufacturing.

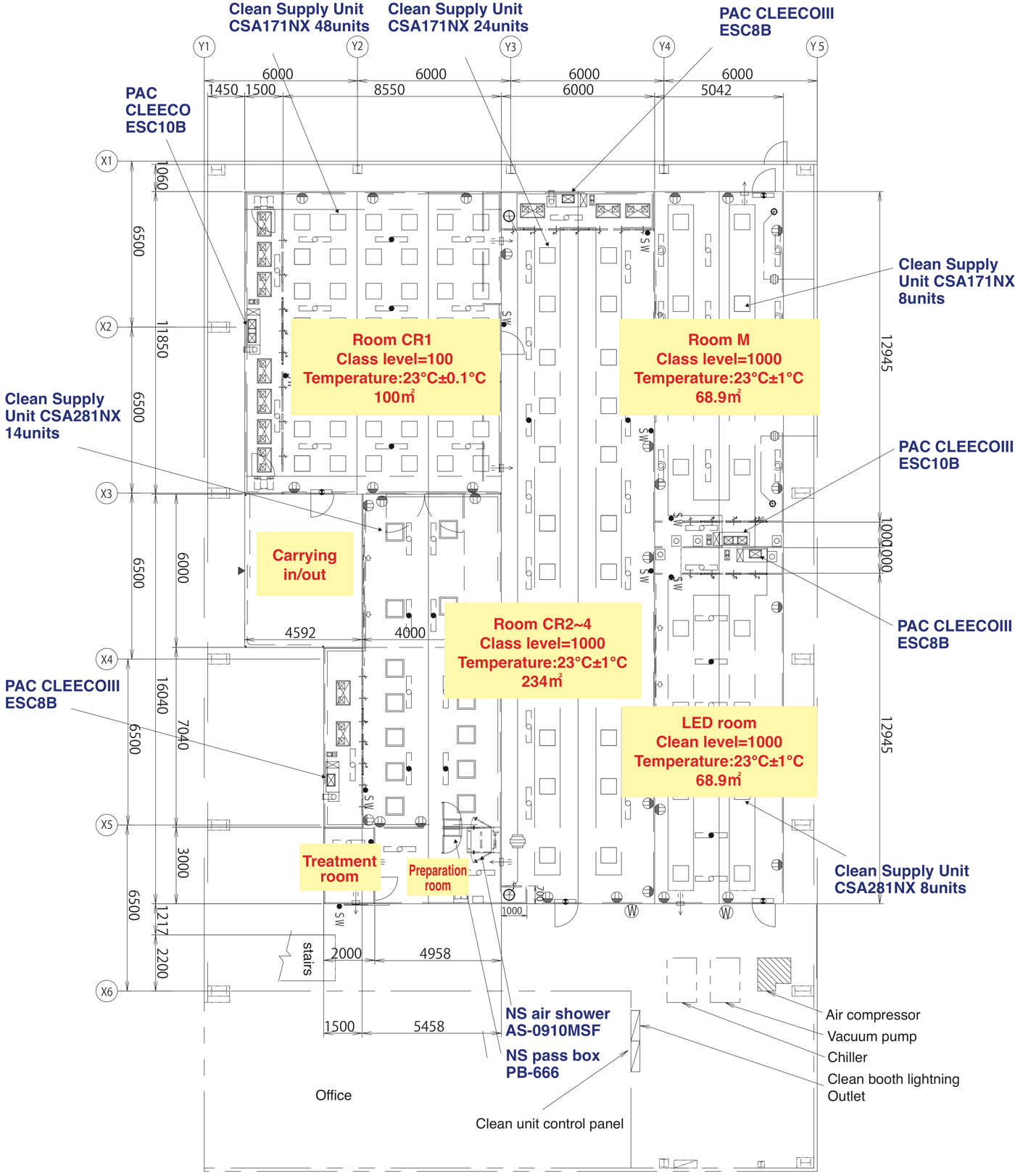

We were the first to set up a cleanroom that is Class 100 or cleaner in Okinawa.

*About the number of particles of dust: There are about 1 million particles of dust in ordinary offices, and about 50,000 in operating rooms at hospitals.

(*The number of particles of dust: the number of particles of size 0.5 µm or larger per cubic foot of air)

Highly temperature-controlled, constant temperature environment.

“The products we manufacture are highly temperature dependent, and the temperature change in the manufacturing environment affects the accuracy due to the expansion and the contraction of metal, and leads to defective products. Therefore, it is necessary to always maintain a certain temperature inside the cleanroom, so we have to control the temperature 24 hours a day, 365 days a year.

The temperature in our cleanroom is set at 23℃ all year round, and as the surrounding temperature gets closer to that, the cost of energy gets lower. The average temperature for the past ten years in Okinawa where the facilities are located is 23℃, which is the same as the set temperature in the cleanroom. Thus, we can save a lot on the cost of controlling the temperature, and by reducing strain on the facilities, we can prolong the durability.”

We remove dust in the treatment room so we do not bring dust into the factory.

We prepare the equipment to bring in and out.

Gallery of facilities pictures

| Equipment | Specification |

|---|---|

| Cleanroom | Class 100, Class 1000 |

| Metallurgical microscope | Resolution: 0.26µm |

| Laser microscope | Resolution: lateral 0.12µm depth: 0.01µm |

| Scanning electron microscope | Secondary electron resolution capability: 3.0nm (Acceleration Voltage 30kV, WD=5mm, High Vacuum Mode) 7.0nm (Acceleration Voltage 3kV, WD=5mm, High Vacuum Mode) Reflection electron resolution capability: Magnification: x5~x300,000 / x7~800,000 Maximum Sample Measurement: 200mm in diameter |

| ZYGO | Fizeau interferometer Depth resolution: λ/2 interference fringe detectable |

| Constant temperature booth | 23℃ ±0.03℃ |

| Film thickness gauge | FILMETRICS:F20 |

| Non-contact high resolution profilometer | Scanning length: 100mm Minimum sampling interval: 50nm Resolution: 1Å |